About this project

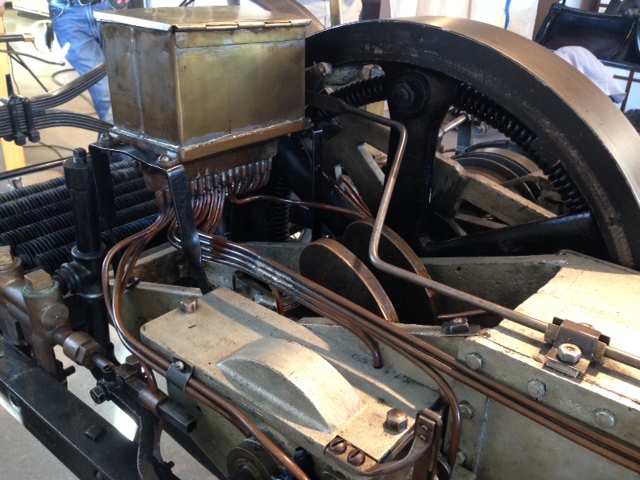

BRH was contracted by Lehigh University to assess and conserve their 1899 Packard No. 1 prototype. The vehicle had last been driven in 2004. The client requested that a video documenting the Packard’s engine running one last time before the treatment as they were unsure if it would be run again.

What we did

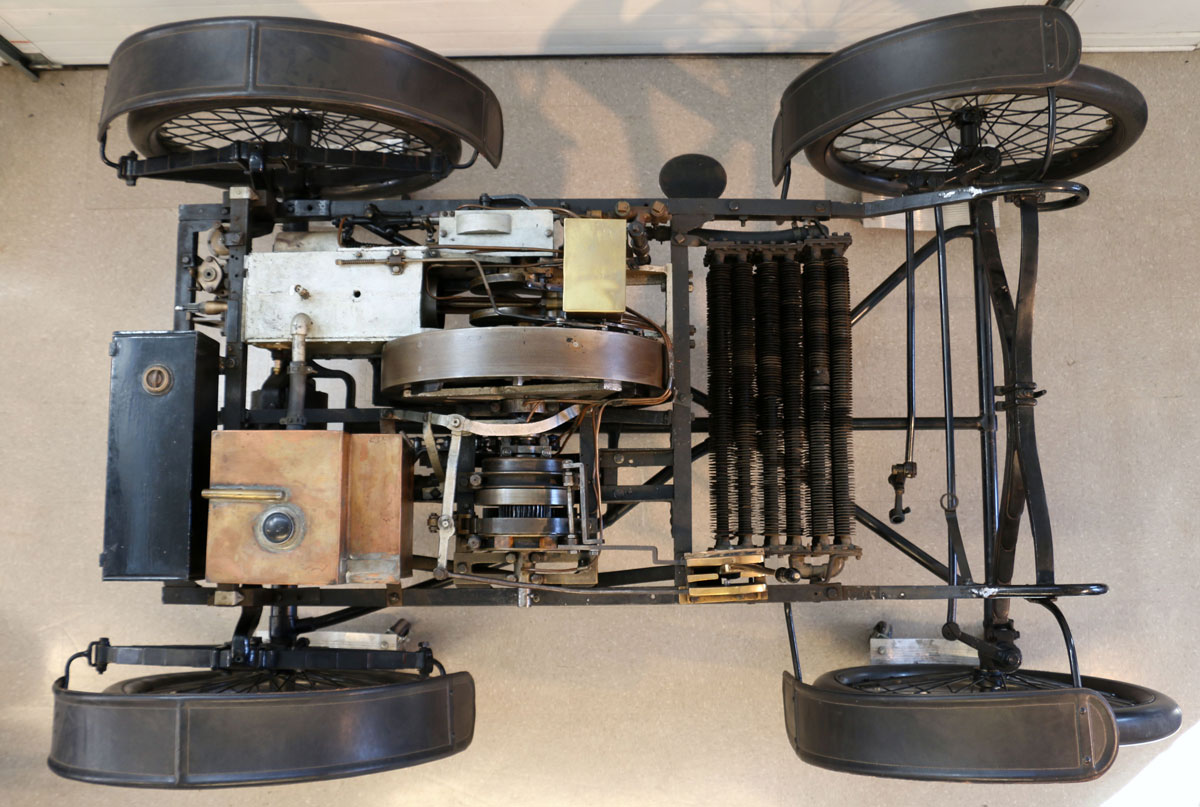

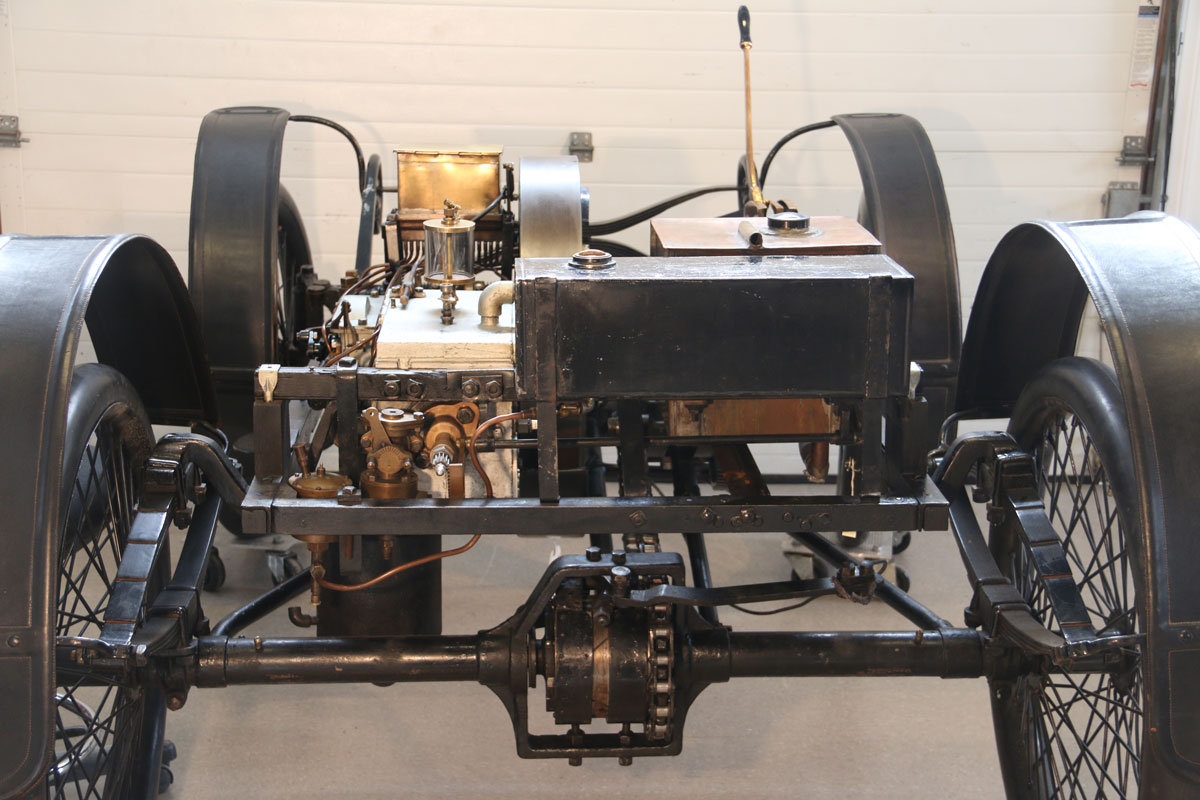

The vehicle was transported to our studio and photo documented from all angles prior to beginning any treatment as per AIC Guidelines for Practice. The Packard was placed on padded jack stands to remove the weight from the wheels. The fenders, dash, rear facing jump seat, seat cushions, gear shift lever, and steering tiller were labeled and carefully removed.

The fuel tank, lines, and carburetor were removed to clean a moderate degree of varnish that had built up. The cooling system and radiator were repeatedly flushed, removing a significant degree of iron corrosion scale before being dried. Corrosion, found on unpainted iron components were mechanically reduced and stabilized.

The body was unbolted from the chassis, lifted and placed into padded supports to facilitate treatment. The splits in the side panels were cleaned, re-aligned and adhered, filled, before being masked off and airbrushed using reversible pigment that matched the original color. Flaking paint was consolidated using a reversible heat set resin. The textiles and leather fenders were also cleaned, repaired, and stabilized.